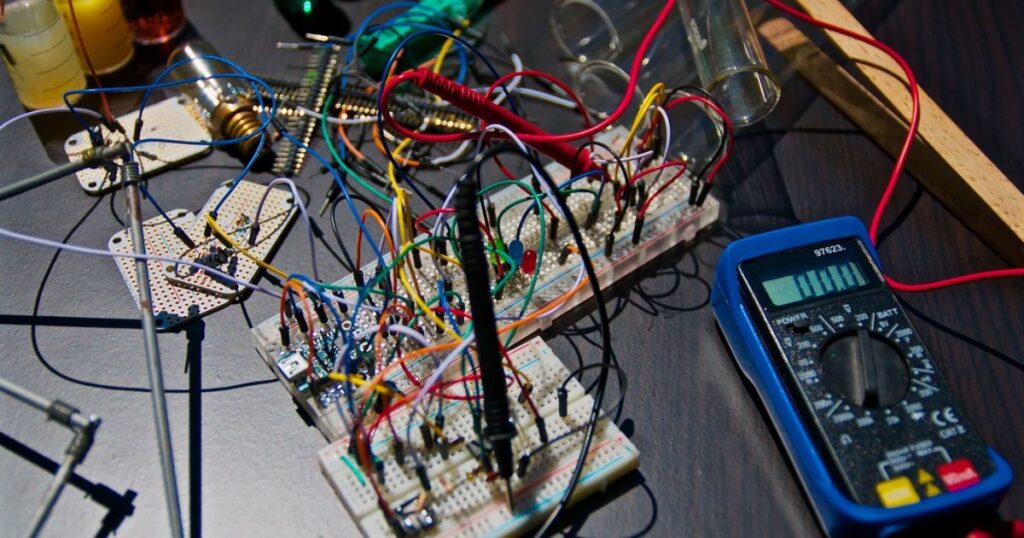

The electronic testing device is a powerful tool designed to analyze, validate, and ensure the optimal performance of electronic circuits. This compact device serves as a reliable assistant in identifying faults, measuring signals, and validating electronic components with precision.

Simplifying complex diagnostics, is an essential gadget for engineers and technicians, providing a streamlined solution for efficient electronic testing and troubleshooting. How do electronic testing devices protect your devices? Electronic testing devices ensure device protection by identifying potential issues in circuits and preventing malfunctions before they occur.

Electronic devices ensure your devices’ safety by identifying potential issues before they escalate, preventing malfunctions, and safeguarding against unexpected failures. They help users identify potential faults, ensure optimal functionality, and maintain the reliability of electronic devices.

Electronic Testing Device Designed for Ease of Use

Electronic testing devices designed for ease of use embody a commitment to enhancing the overall user experience. These instruments prioritize simplicity and accessibility in their design, ensuring that users, regardless of their technical proficiency, can efficiently navigate and utilize the device. The interfaces of these devices are thoughtfully crafted, featuring intuitive controls and user-friendly displays that facilitate a smooth testing process. One key aspect of user-friendly electronic testing devices is the incorporation of advanced features that simplify complex testing procedures.

Automatic measurement setups and guided troubleshooting wizards empower users to conduct tests without extensive technical knowledge, reducing the barriers to entry for individuals with varying levels of expertise. These devices often prioritize clarity in their user interfaces, allowing users to easily interpret results and make informed decisions based on the data obtained. The ergonomic considerations play a crucial role in the design of these devices. Engineers take into account factors such as device size, weight, and control placement to ensure comfort during prolonged usage. The objective is to create tools that not only perform intricate testing functions but also prioritize user comfort, making electronic testing accessible, efficient, and user-friendly across a spectrum of applications and industries.

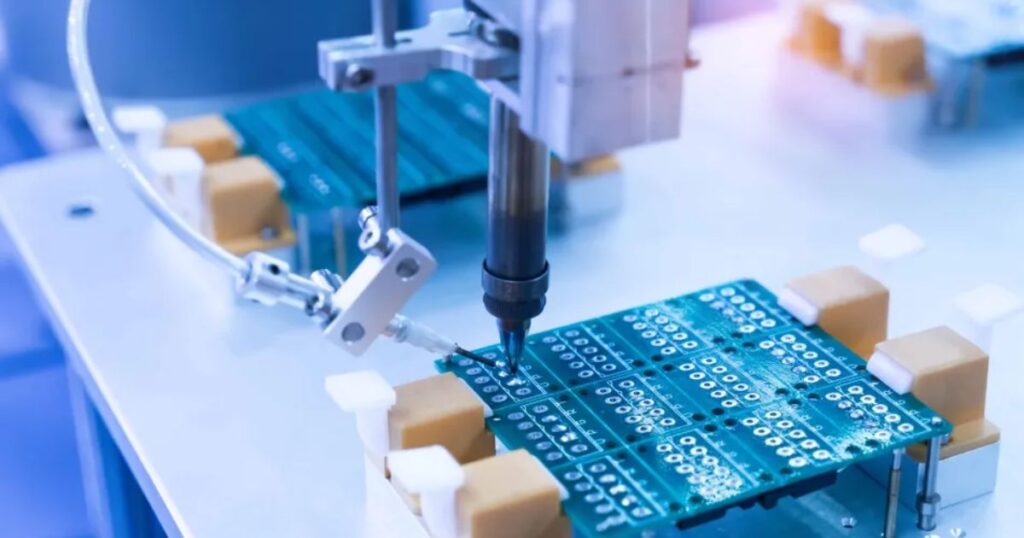

Types of Electronic Testing Devices

Electronic testing devices are instruments designed to assess and ensure the proper functioning of electronic components and systems. These devices play a crucial role in quality control, troubleshooting, and maintaining the reliability of electronic equipment. Several types of electronic testing equipment serve specific purposes in evaluating different aspects of electronic devices.

Oscilloscopes

Oscilloscopes are vital tools for visualizing and analyzing electrical signals over time. They provide a graphical representation of voltage changes, aiding engineers in diagnosing issues and optimizing circuit performance.

Multimeters

Multimeters are versatile instruments that measure various electrical parameters, including voltage, current, and resistance. They are fundamental for basic electrical testing and troubleshooting.

Signal Generators

Signal generators produce precise electrical waveforms, allowing engineers to simulate real-world conditions and assess how electronic systems respond to different signals.

Spectrum Analyzers

Spectrum analyzers are used to analyze the frequency domain of signals. They help identify signal characteristics, and interference, and ensure optimal signal quality in communication systems.

Logic Analyzers

Logic analyzers are essential for debugging digital circuits. They capture and display multiple digital signals simultaneously, facilitating the analysis of complex interactions within digital systems.

LCR Meters

These are used to measure inductance, capacitance, and resistance, LCR meters are essential for evaluating the electrical properties of passive components.

EMI/EMC Testers

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) testers assess the susceptibility and emissions of electronic devices to ensure compliance with regulatory standards.

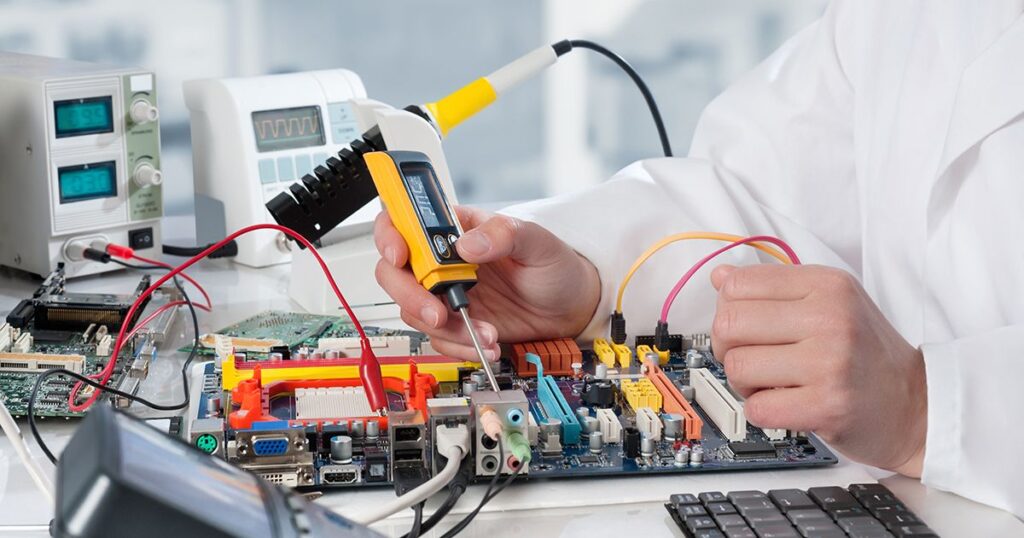

Preventive Maintenance with Electronic Testing

Preventive maintenance using electronic testing is a proactive approach to ensure the longevity and reliability of electronic systems. By regularly assessing electronic components, potential issues can be identified and addressed before they escalate, reducing the risk of unexpected failures. This practice involves routine checks using electronic testing devices to measure parameters like voltage, current, and resistance, ensuring that components operate within specified limits. By catching and resolving issues early, preventive maintenance minimizes downtime, extends the lifespan of equipment, and ultimately saves on repair costs.

Electronic testing in preventive maintenance is particularly crucial for critical systems, such as those in industrial settings or data centers, where disruptions can have significant consequences. Regular assessments using tools like multimeters, oscilloscopes, and thermal imaging cameras help maintain optimal performance, identify deteriorating components, and prevent potential safety hazards. Overall, integrating electronic testing into preventive maintenance strategies is an efficient way to enhance the reliability and efficiency of electronic systems, ensuring they operate smoothly and meet performance expectations.

Frequently asked questions

Why is electronic testing important?

Electronic testing is crucial because it ensures that electronic devices and components work properly. It helps identify and fix issues early, improving the reliability and quality of electronic products.

Can electronic testing devices be used by non-experts?

Yes, many electronic testing devices are designed with user-friendly interfaces and intuitive controls, making them accessible to both experts and individuals with limited technical expertise. Some devices also feature guided troubleshooting features to assist users.

What are some common features of electronic testing devices?

Common features include graphical interfaces, touchscreen controls, automatic measurement setups, and guided troubleshooting wizards. These features enhance user experience, streamline testing processes, and make the devices more efficient.

Are electronic testing devices user-friendly for non-technical users?

Many electronic testing devices are designed with user-friendly interfaces, intuitive controls, and features like automatic measurement setups. This makes them accessible to users with varying

What types of measurements can electronic testing devices perform?

Electronic testing devices can measure various parameters, including voltage, current, resistance, frequency, and more. The specific measurements depend on the type of device, such as oscilloscopes, multimeters, spectrum analyzers, and logic analyzers.

Conclusion

Preventive maintenance using electronic testing is a proactive approach to ensure the longevity and reliability of electronic systems. By regularly assessing electronic components, potential issues can be identified and addressed before they escalate, reducing the risk of unexpected failures. This practice involves routine checks using electronic testing devices to measure parameters like voltage, current, and resistance, ensuring that components operate within specified limits. By catching and resolving issues early, preventive maintenance minimizes downtime, extends the lifespan of equipment, and ultimately saves on repair costs.

Electronic testing in preventive maintenance is particularly crucial for critical systems, such as those in industrial settings or data centers, where disruptions can have significant consequences. Regular assessments using tools like multimeters, oscilloscopes, and thermal imaging cameras help maintain optimal performance, identify deteriorating components, and prevent potential safety hazards. Overall, integrating electronic testing into preventive maintenance strategies is an efficient way to enhance the reliability and efficiency of electronic systems, ensuring they operate smoothly and meet performance expectations.

Meta Description

Discover how electronic testing devices can provide precision and reliability. Ensure optimal performance and ease troubleshooting with oscilloscopes and multimeters.